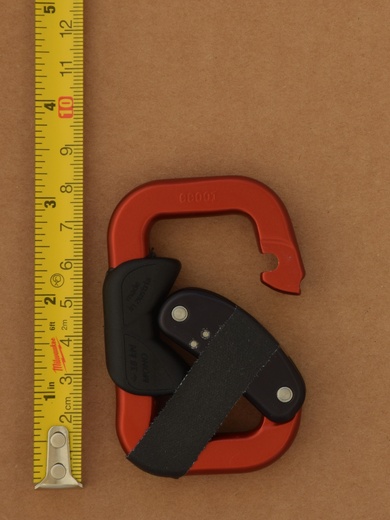

| Name: | AustriAlpin Stratus |

| Category: | slide lock |

| Locking Type: | full-auto |

| Locks: | single |

| Unlock Style: | slide |

| Shape: | trapezoid |

| Material: | aluminum |

| Profile: | flat |

| Nose: | notch & pin |

| Nose Guard: | none |

| Rivets: | dimpled: ring dimpled |

| Gate Shield: | none |

| Anti Crossload: | interior spur: spine |

| Weight: | 63.6 g |

| Dimensions: | Length: 78.24 mm Width: 55.9 mm Depth (basket end): 7.96 mm Gate Opening: 9.66 mm |

| Strength Ratings: |  18 kN 18 kN |

| Other Markings: | Forged: (AA graphic logo) AUSTRIALPIN | 00OOl Injection Molded: (AA graphic logo) AUSTRIALPIN STRATUS ALLOY|(rating) MONO made in austria |

| MSRP: | $19.85 (2023) |

| Collection Criteria: | ★ Manufacturing, Engineering, or Design |

| Summary: | paragliding carabiner, anti-crossloading spine spur |

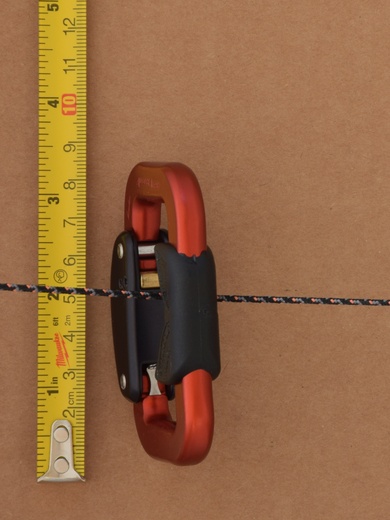

| Description & Commentary: | Designed to meet the needs of paragliding, (21 mm in length) flat ends evenly load harness & riser webbing, while an injection molded spine-spur helps to keep the load properly aligned. The gate body is machined from a single aluminum piece, with gate and hinge pins recessed and heads formed using an annular punch. Two smaller pins hold a brass locking slider inside the gate - each pin fixed in place by deforming the gate body with an annular punch. The locking piece hinges on the pin closest to the carabiner interior and the other as a stop against which a spring presses the locking piece. When unlocking, the gate limits the travel of the brass slider. Technically the locking piece pivots rather than slides into the unlocked position. I've included this carabiner in the slide-lock category because the user interacts with the protected locking piece much like a slide-lock mechanism. Interestingly, the AustriAlpine slide lock almost behaves like a button lock: the short pivoting action, combined with an angled upper surface and light spring, will permit the user to unlock the carabiner gate with a direct press on the upper angled surface - no sliding needed. Unlike most carabiners, the bottom of the gate spring and entire pusher piece are exposed. There is also a large gap below the brass slider, exposing the locking spring (distinct from the gate spring). In comparison with carabiners used in caves, canyons and on cliffs, paragliding carabiners tend to operate in a cleaner environment - which greatly reduces the risk of foreign material entering these openings (and jamming the gate). All edges of the gate body are impressively well rounded and smooth - there are no sharp edges to cause excessive wear and tear on nearby softgoods. This carabiner does not carry a CE rating, probably due to the paragliding design requirements. Unlike most other carabiner users, paragliders subject their carabiners to extremely high cycles of (relatively) low loads for long periods of time - basically loading the connector until the gate catches on the nose, then unloading. This places stress on the spine side of the carabiner. DHV, the German paragliding association has said these connectors are subject of typical loads from 10-110 (and up) kg at up to 26 times a second. Considering the length of paragliding flights, this can cause material fatigue that would basically be impossible to reach in climbing and most other rope disciplines. As such, AustriAlpin recommends retiring this connector within 1500 flight hours or 5 years from first use. A dramatic spine failure (of a different brand/model carabiner) can be seen in three frames from this this paragliding video (timestamped, no serious injuries). Few conclusions can be drawn from this event, as connector history was unknown, and subjected to heavier loads due to the tandem flight. While unnerving, this event is extremely rare and easily avoided by retiring connectors in accordance with their manufacturer's recommendations. See also: AustriAlpin Rondo HMS Slide Lock |

| MPN: | FP25B-R |

| Manufacturer Color: | red |

| Technical Notice: | Technical Notice |

| Product Info Sheet: | Product Info Sheet |